Student-Designed Robots Tackle Snow, Sewers, and Infectious Disease

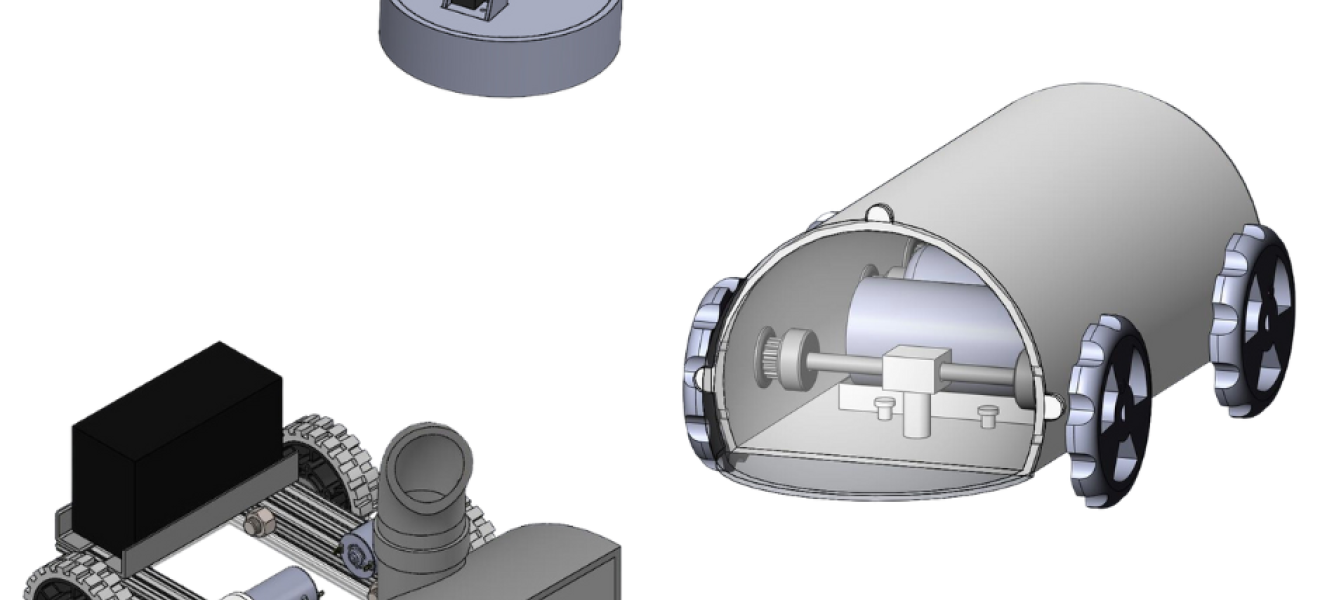

From top, Hazardous Area Robotic Arm (HARA), Sewer Scout, and Snow Roomba

A snow-removing Roomba, hazardous area robotic arm, and a sewer inspector are among robots created by teams of Wentworth Institute of Technology students and professors.

The projects—overseen by Professors Bo Tao and John Voccio within the School of Engineering—are recent examples of the robotic wizardry that Wentworth students have been creating.

Snow Roomba

With the winter season posing risk of injuries due to shoveling and heavy snow removal, the Snow Roomba utilizes GPS navigation technology to combat these dangers. By combining the efficient design of a snowblower with the precision of a robotic vacuum-style GPS, the prototype device aims to decrease and potentially eliminate the number of hospital visits caused by winter cleanup.

The Snow Roomba project emerged as a response to the increasing number of heart attacks and other injuries associated with snow-related tasks. The design process involved crafting a sturdy base with a front attachment to effectively clear snow. The team opted for a snow blower as the primary snow removal mechanism due to its faster performance.

The device is equipped with a flight controller running Ardupilot Rover, allowing for autonomous driving. Additionally, three DC motor speed controllers, a GPS, a compass, and an RC receiver enable manual control and mode changes for the robot.

The interdisciplinary nature of the project required expertise in mechanical engineering, electrical engineering, robotics, and other relevant fields. Through the collaboration of these disciplines and the application of knowledge gained from hands-on labs and humanities courses, the team of Voccio and students Greg Lagana, Juan Jose Boschetti Muñiz, and Aiyana Weekes-Tulloch have developed a consumer-friendly device that could revolutionize snow removal and mitigate the risks associated with winter clean-up.

Download the Snow Roomba poster

Hazardous Area Robotic Arm (HARA)

Another team—consisting of Tao and students Erin Morton, Rob Moran, Craig Rich, and RJ Woodward—developed a robotic arm that replicates the movements of its user, offering a unique solution for maintaining a safe distance in environments prone to infectious disease exposure.

The robotic arm, known as HARA, utilizes a control sleeve worn by the user to mimic their motions accurately. Initially designed to assist hospital workers in remotely caring for patients, HARA has evolved to benefit essential employees in various fields, including store cashiers and toll booth operators, who frequently come into contact with the public and potential germs.

The HARA project was driven by the group's aim to create a solution that would protect those most vulnerable to developing COVID-19. By wearing the control sleeve, workers can control HARA's movements, providing care or completing tasks from a distance. The placement of sensors on the arm, such as flex sensors along the fingers and wrist, enables accurate measurement of bending, rotation, and movement, ensuring precise replication of the user's actions.

The team began with brainstorming and extensive research before assigning roles and dividing tasks. The creation of a CAD model and Arduino code, along with determining loading specifications and building schematics, formed the initial stages. Assembling the robotic arm was followed by rigorous testing and subsequent improvements to enhance its functionality. Through this meticulous process, the team successfully achieved measurable objectives, including a payload capacity of 0.25 lbs, a reaction time of 0.1 seconds, and a radius of motion of one foot.

The Sewer Scout

Tao and students Preston Rutledge, Hillary Valenzuela, and Caleb Weldon created the Sewer Scout based on the need for efficient and clear image inspection systems. Recognizing the limitations of existing inspection devices, which often lack clear interior images and rely on manual pushing through pipes, the team aimed to create a superior and more efficient design.

The design criteria for the Sewer Scout included compact dimensions, with a width and height smaller than four inches, while ensuring its ability to travel a minimum of 10 feet in straight pipes. Additionally, the device must be capable of transmitting footage back to the user and remain connected with its tether wires while submerged and in motion.

Using SolidWorks software, the team created separate components that were later assembled, enabling them to visualize how each part interacted and determine the necessary dimensions. Factors such as speed and power were also calculated to ensure steady and clear camera visuals.